Animal Welfare Policy: We are committed to the humane treatment of animals. Our animal welfare policy prohibits the use of fur, angora, and mohair, as well as practices including live plucking and mulesing. For more details, visit https://gapinc-prod.azureedge.net/gapmedia/gapcorporatesite/media/images/values/sustainability/documents/2023/gap-inc-animal-welfare-policy-2023.pdf.

Better Cotton: Gap partners with Better Cotton to help improve cotton farming globally. Better Cotton is sourced via a chain of custody model called mass balance. This means that Better Cotton is not physically traceable to end products, however, Better Cotton farmers benefit from the demand for Better Cotton in equivalent volumes to those we ‘source’. As Gap progresses toward our commitment to use 100% more sustainable and traceable cotton by 2030, we purchase Better Cotton credits to help account for the remaining volume of cotton that we source.

Cotton in Conversion to Organic: Gap is supporting cotton growing communities during the three-year transition toward certified organic farming and away from conventional agricultural practices, which use synthetic pesticides and fertilizers.

Eastman Naia™: Eastman Naia™ cellulosic fiber is derived from wood pulp that is sourced from responsibly managed pine and eucalyptus forests. Naia™ is produced in a closed-loop process where solvents are recycled back into the process for reuse.

Lenzing™ Ecovero™: LENZING™ ECOVERO™ fibers are derived from the natural raw material wood from controlled or certified wood sources. The fibers are made with at least 50% less water consumption compared to generic (unbranded) viscose based on LCA standards (ISO 14040/44) and available via Higg MSI (Version 3.7).

Livaeco by Birla Cellulose™: Livaeco™ is fiber derived from wood, a renewable resource, which has been sourced from responsibly managed forests. It is manufactured using a stringent closed-loop process that uses less energy and water as compared to generic viscose.

with significantly lower emissions and less water than generic viscose.

More Sustainable Materials: Our “more sustainable materials” include recycled materials, regenerative cotton, organically grown cotton, cotton-in-conversion to organic, U.S. Cotton Trust Protocol verified cotton, Tencel™, Tencel™ X Refibra™, Lenzing™ Ecovero™, Livaeco by Birla Cellulose™, Eastman Naia™, and partially plant-based EVA.

Organically Grown Cotton: Organically grown cotton is grown without the use of harmful synthetic pesticides and fertilizers.

Organic Farming: Organic farming aims to support healthy ecosystems and biodiversity by encouraging practices like crop rotation, prohibiting genetically modified seeds, maintaining healthy soils, and applying organic fertilizers and manures instead of synthetic inputs.

Preferred Fibers Toolkit: Our toolkit includes an evaluation of raw material choices that builds upon data inputs from the Higg Materials Sustainability Index. It also incorporates other holistic indicators to consider environmental and social considerations. Building on the toolkit, Gap Inc. and Textile Exchange are proud to announce the public release of the Preferred Fiber and Material Matrix, a resource for sourcing and design teams to inform companies on meeting their sustainability goals.

Learn more at textileexchange.org/pfm-matrix

Recycled Materials: Recycled materials are recovered or diverted from the waste stream either during the manufacturing process (pre-consumer) or after consumer use (post-consumer). Using recycled materials helps us minimize our impact on the planet. Compared to virgin materials, using recycled materials helps to conserve resources and reduce waste.

regenagri®: regenagri® is a global regenerative agriculture framework for securing the health of the land and the wealth of those who live on it. It supports farms and organizations to transition to holistic farming systems that increase soil health, encourage biodiversity, and enhance climate resilience. regenagri® provides standards and digital tools to certify impact and to assure the integrity of regenagri certified products from farms to finished products. Learn more at https://regenagri.org/

Regenerative Cotton: Regenerative cotton agriculture is a holistic approach to farming practices that enriches soil and measurably improves water retention and local biodiversity.

Tencel™ x Refibra™: TENCEL™ Lyocell fibers produced with REFIBRA™ technology transform recycled cotton textile waste into new fibers.

TENCEL™ fibers: TENCEL™ lyocell and modal fibers are derived from the natural raw material wood from controlled or certified wood sources. The fibers are made with at least 50% less water consumption compared to generic (unbranded) viscose based on LCA standards (ISO 14040/44) and available via Higg MSI (Version 3.7).

U.S. Cotton Trust Protocol Cotton: As members of the U.S. Cotton Trust Protocol, we participate in a program for U.S.-grown cotton that supports best practices and continuous improvement in key areas, including soil health, water management. For more details, visit trustuscotton.org.

Wood-Derived Fabric Policy: In partnership with CanopyStyle, a third-party sustainable fashion and forestry initiative, we set this policy to help ensure our suppliers do not use wood from ancient, endangered, high-conservation or high carbon–value forest areas to make cellulose-based textiles, including rayon, modal, viscose, and lyocell.

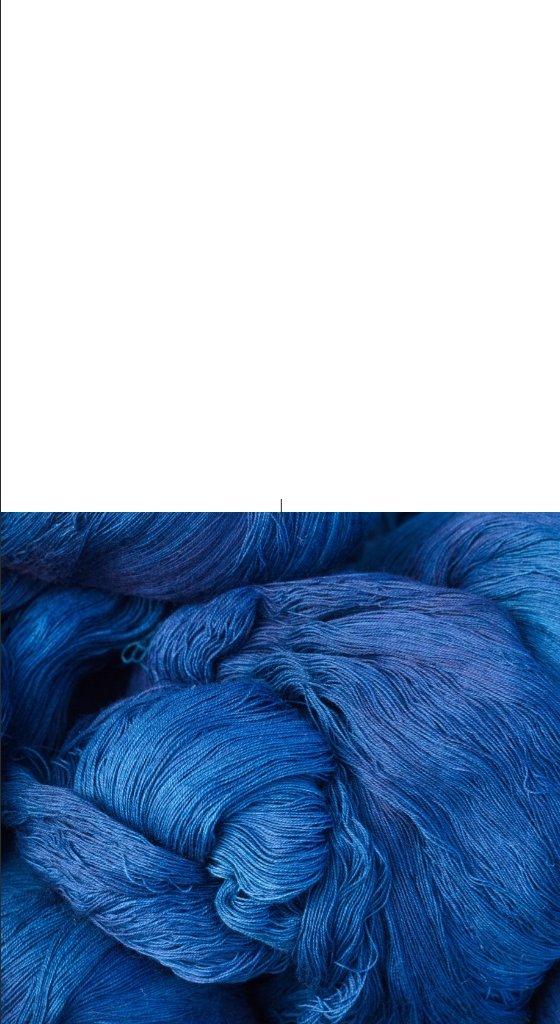

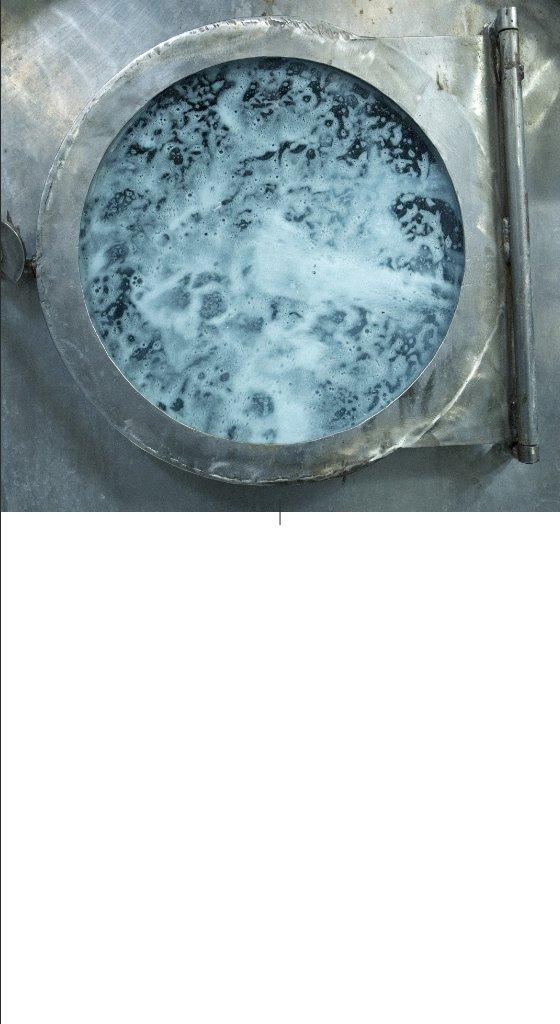

Washwell: Developed in 2016, our Washwell program for denim, woven bottoms (like khakis),and knits, uses at least 20% less water compared with conventional wash methods. Non-washed products such as those made with raw denim or faux leather are not eligible for Washwell. We've saved over a billion liters of water through Washwell since 2016.

Water-Quality Program: Developed in 2004, the Gap Inc. Water-Quality Program requires denim-producing facilities to not emit any discharge to local waterways, protecting local communities and watersheds while mitigating impact on the planet.

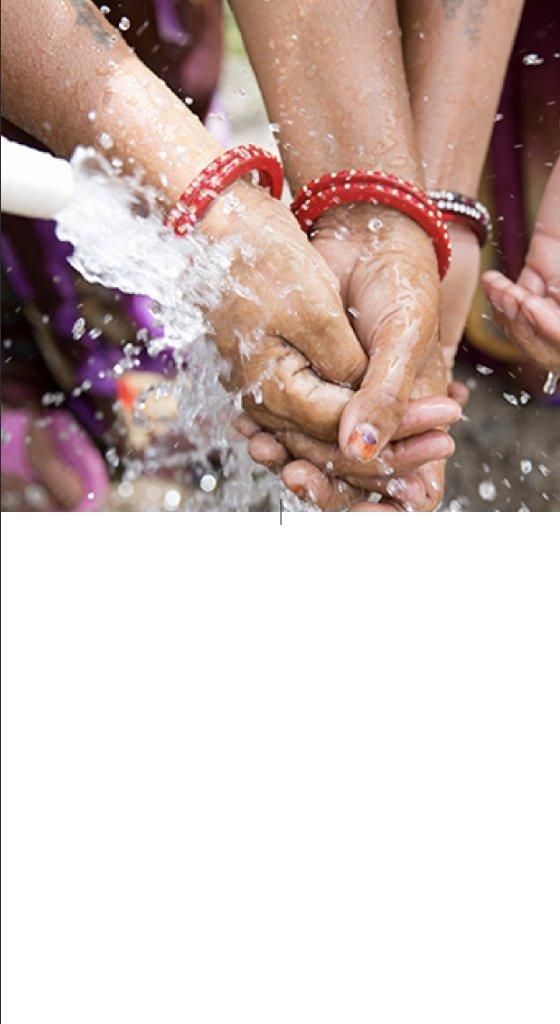

Women + Water We believe access to clean water is a fundamental right, so we work with key partners to catalyze women as water champions to advance lasting solutions for water access in their communities. Between 2017-2023, the USAID Gap Inc. Women + Water Alliance empowered more than 2.5 million people touched by the apparel industry in India to improve their access to clean water and sanitation. The program has since evolved to include new partners in the Women + Water Collaborative, and we continue to expand access to clean water and sanitation through additional initiatives. Learn more at gapinc.com.

Manufacturing Restricted Substances List (MRSL): We expect our suppliers to comply with the Zero Discharge of Hazardous Chemicals (ZDHC) MRSL, which prohibits use of chemicals of concern in production. We also expect wet processors to comply with the ZDHC Wastewater Guidelines for wastewater testing to monitor adherence to the MRSL.

Per- and Polyfluoroalkyl Substances (PFAS): Gap Inc. is committed to the elimination of PFAS based finishes for our products. In 2022 and 2023, Gap Inc. did not source any fabrics intentionally treated with per- and polyfluoroalkyl substances (PFAS).

Restricted Substance List (RSL): Our Restricted Substances List prohibits suppliers from using certain chemicals that are harmful to people and the planet. In addition to protecting customers, our policies were put in place to address environmental pollution and protect garment workers from exposure to harmful chemicals. Gap Inc. is a founding member of the Apparel and Footwear International RSL Management (AFIRM) Group. Since 2008, our suppliers have been expected to comply with the AFIRM RSL, which sets limits on chemicals in finished products.

Gap Inc. Code of Vendor Conduct: Since launching our Supplier Sustainability Program in 1994, we transformed our approach to improving facility working conditions by developing innovative, holistic programs that leverage assessments (audits) and remediation of our supply chain to ensure compliance to our Code of Vendor Conduct. We believe that by working together, we can achieve our commitments to improve workers’ well-being, protect human rights, reduce environmental impacts, and improve business performance.

Gender Based Violence Prevention & Response: Gap Inc.’s Supplier Sustainability team works with our suppliers to help build an environment where they clearly define and implement policies to prevent and address gender-based violence. We aim to help our suppliers raise awareness about this issue and the rights and responsibilities of female and male employees, including managers.

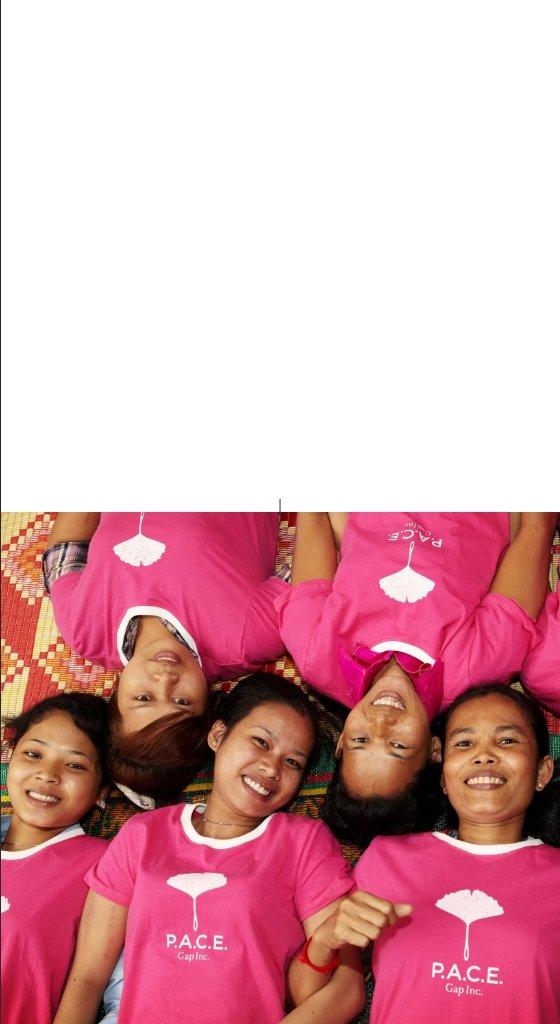

Personal Advancement & Career Enhancement Program (P.A.C.E.): P.A.C.E. is Gap Inc.’s educational program that helps the women who make our clothes build the skills, knowledge, confidence, and resilience needed to advance in work and life. Learn more at gap.com/pace. Gap Inc. has begun integrating P.A.C.E. Workplace into Reimagining Industry to Support Equality (RISE), an industry collaboration created to advance gender equality in global garment, footwear, and home textiles supply chains.

Reimagining Industry to Support Equality (RISE): In 2019, Gap Inc. leveraged our P.A.C.E. program to became one of the founding members of Rise, along with Better Work, Business for Social Responsibility’s (BSR) Herproject and Care, working with support from the International Center for Research and Women (ICRW).

Rise harnesses the power of collective action to empower women workers, embed gender equality in business practice and catalyze policy and systems change, by aligning women’s empowerment training and skill-building efforts across the apparel industry. Rise will focus on building and deploying sustainable, systemic, and scalable programs that promote gender equality in global supply chains.

Strategic Factories: Strategic factories represent 80% of production costs for Gap brand.

Supervisory Skills Training: Gap Inc. launched the Supervisory Skills Training (SST) program to reach mid-level managers and provide them with the skills to improve communication with workers. SST gives supervisors and middle managers a deeper understanding of leadership and supervisory concepts.

Workplace Cooperation Program (WCP): We believe that improving dialogue and relations between workers and management can help prevent labor disputes, resolve problems, give greater voice to workers, and improve productivity and competitiveness. The Gap Inc. Workplace Cooperation Program (WCP) sets up committees that are comprised of both workers and management representatives who are trained to work together to help address workplace issues, from overtime and worker well-being to washroom sanitation and better quality of food in the canteen.

Circularity: Materials are valuable, and one of the best things we can do is keep those materials in use for as long as possible. Joining the circular economy means shifting our thinking about design, how we wear and care for products, and where products eventually go, so that they can get reused and recycled. To do so, we are building programs to address product end of life and create circular design systems that reduce waste and increase recycling, upcycling, and reuse. Some of these efforts include:

Plastic Waste: Gap Inc. is working towards its 2030 commitment through The Fashion Pact to eliminate unnecessary and problematic plastic packaging as defined by the Ellen MacArthur Foundation. We aim to achieve this goal through a combination of methods — reducing packaging where possible and converting to bio-based materials. For packaging that can’t be eliminated, we plan to maximize recycled content or divert waste from landfill through recycling.

The Jeans Redesign: The Jeans Redesign is creating solutions for a world where clothes are kept in use. In February 2019, the Ellen MacArthur Foundation gathered insights from more than 80 industry experts from across academia, brands, retailers, manufacturing, collectors, sorters, and non-governmental organizations to collaboratively define design parameters to make jeans fit for a circular economy. By using The Jeans Redesign guidelines, we’ve created two collections of denim that were made to be used more, made to be made again, and made from safe and recycled, or renewable inputs.

thredUp: Gap partners with thredUp to reduce our impact on the planet by extending the life of clothing. thredUp is a convenient way to clean out your closet. Order a Gap x thredUp Clean Out Kit and turn gently used clothes into Gap shopping credit.

Upcycling: When materials are re-used in a way that adds value to the product, we call that upcycling. The opposite of upcycling is downcycling — still a form of recycling, but one where the new product has less value than the original.